Since the geometry on the container (measurement together with opening on the container) along with the pace of the road are elements that are variable in using an aseptic processing line, suitable mix of these aspects, ideally in the extremes, must be Utilized in the qualification of the road. A rationale for merchandise applied need to be documented.

FARRAR® has two various methods to knowledge our merchandise. At our headquarters in Davidson, NC, our BioSolutions space consists of completely operational ULC models with typical materials handling possibilities - feel free to go to this House to prepare your undertaking and get the job done with our design group over a customized content handling Resolution that matches your approach.

It’s the cleanest room in the medical center, but most of us won't ever phase foot in it. Pharmacies and compounding laboratories certainly are a sizzling subject from the overall health care earth since the US Pharmacopeial Conference’s (USP) revised guidelines necessitate new pharmacy design to fulfill USP 797 and USP 800 compliance.

Staff Contamination: Gowning protocols be certain that human operators tend not to introduce contaminants in to the cleanroom surroundings.

Detrimental Strain. To keep the move of contamination in a single path, air is pulled out of the room and right fatigued outdoors. Once again, mainly because design concentrates on safety, it's important that State-of-the-art mechanical devices regularly pull air out in the room.

The 4000 Sequence Controlled Price Chamber is designed to freeze equally luggage and bottles making use of pressured air as opposed to Call plates like a plate freezer. Personalized profiles can be designed comparable to a plate freezer, however.

These programs enable for more exact temperature and stress Handle, making certain consistent sterilization final results whilst minimizing Electrical power usage.

Sterile Subject —In aseptic processing or in other managed environments, it's the Area at the extent of or over open solution containers, closures, or product or service itself, where by the probable for microbial contamination is highest.

Now, drug brands are challenged to build and release new biologics at an unparalleled rate. Pivoting to satisfy world wide distribution demand is vital and involves optimization in production and distribution.

Yet another thrilling technologies is the usage of chilly plasma for sterilization. Chilly plasma can proficiently inactivate microorganisms on surfaces and inside the air with no have to have for top temperatures or severe chemical compounds.

The Extremely-Small Chamber (ULC) Sequence has the chance to freeze product from ambient temperatures to -eighty°C, but it does not allow for specific cooling profiles for example fall and hold or managed temperature adjustments/minute.

Cleanroom – Sterile Pharmaceutical Output – FHNW – This resource information the procedures and infrastructure of a cleanroom facility for sterile pharmaceutical output, including class C and D cleanrooms, a variety of sterilization techniques, and equipment for filling, lyophilization, and Visible inspection.

In pharmaceutical production, sustaining a controlled setting is vital to make certain item protection, efficacy, and regulatory compliance. Cleanrooms Engage in a crucial click here part in this process by supplying a space free of contaminants exactly where medications, biologics, along with other Health care solutions may be manufactured below really controlled circumstances.

However, schedule microbial monitoring need to give enough information and facts to determine which the managed natural environment is operating inside an clean room requirements for pharmaceuticals enough point out of Regulate.

Mr. T Then & Now!

Mr. T Then & Now! Spencer Elden Then & Now!

Spencer Elden Then & Now! Hallie Eisenberg Then & Now!

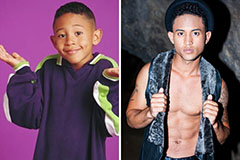

Hallie Eisenberg Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now!